Revolutionizing Piping Projects: The Rise of Lightweight Plastic Pipe Welding Tools

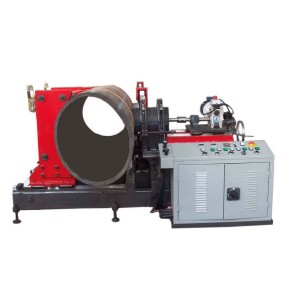

Overview of Lightweight Plastic Pipe Welding Tools

Lightweight plastic pipe welding tools are specialized, portable devices designed to join plastic pipes through heating and fusion techniques. Catering primarily to the needs of the plumbing, HVAC, and construction industries, these tools facilitate seamless connections, ensuring leak-proof and robust piping systems. Their compact size and ease of use make them indispensable for both on-site repairs and new installations.

Key Features and Advantages

● Portability: Their lightweight design allows for easy transportation and use in confined spaces or at elevated heights.

● Efficiency: Streamlines the welding process, enabling faster completion of projects with less physical strain.

● Versatility: Suitable for a wide range of plastic pipe materials and sizes, from small domestic water lines to larger industrial conduits.

● Precision: Delivers accurate and controlled heating, ensuring high-quality welds that meet industry standards.

Applications

The versatility and efficiency of lightweight plastic pipe welding tools make them suitable for various applications, including:

● Water and Gas Distribution: Installation and maintenance of piping systems for residential and commercial buildings.

● Irrigation Systems: Assembly of durable and leak-proof irrigation networks for agriculture.

● Industrial Piping: Fabrication and repair of process piping in manufacturing plants and industrial facilities.

● Telecommunications and Electrical Conduits: Joining of protective piping for cables and wiring.

Selecting the Right Lightweight Plastic Pipe Welding Tool

Choosing the most suitable lightweight plastic pipe welding tool requires consideration of several factors:

● Pipe Material and Diameter: Ensure the tool is compatible with the specific types of plastic pipes and the range of diameters you'll be working with.

● Power Source: Consider whether a battery-operated or corded tool best suits your mobility and power needs.

● Temperature Control: Look for tools with adjustable temperature settings to accommodate different welding requirements.

● Ergonomic Design: A comfortable grip and user-friendly interface can significantly enhance usability and reduce fatigue during extended use.

Tips for Effective Use

● Proper Preparation: Clean and deburr pipe ends thoroughly before welding to ensure optimal fusion.

● Practice and Training: Familiarize yourself with the tool's operation on scrap materials before tackling actual projects.

● Safety Measures: Employ protective gear, such as gloves and safety glasses, and ensure adequate ventilation when welding indoors.

● Maintenance: Regularly clean and inspect your welding tool to maintain its performance and prolong its lifespan.

Conclusion

Lightweight plastic pipe welding tools are reshaping the landscape of pipe installation and repair, offering a blend of convenience, efficiency, and reliability. By equipping yourself with the right tool and adhering to best practices, you can achieve professional-quality welds, ensuring the longevity and integrity of piping systems across a myriad of applications. Whether you're a seasoned contractor or a DIY aficionado, these compact welding solutions are poised to enhance your toolkit and streamline your projects.