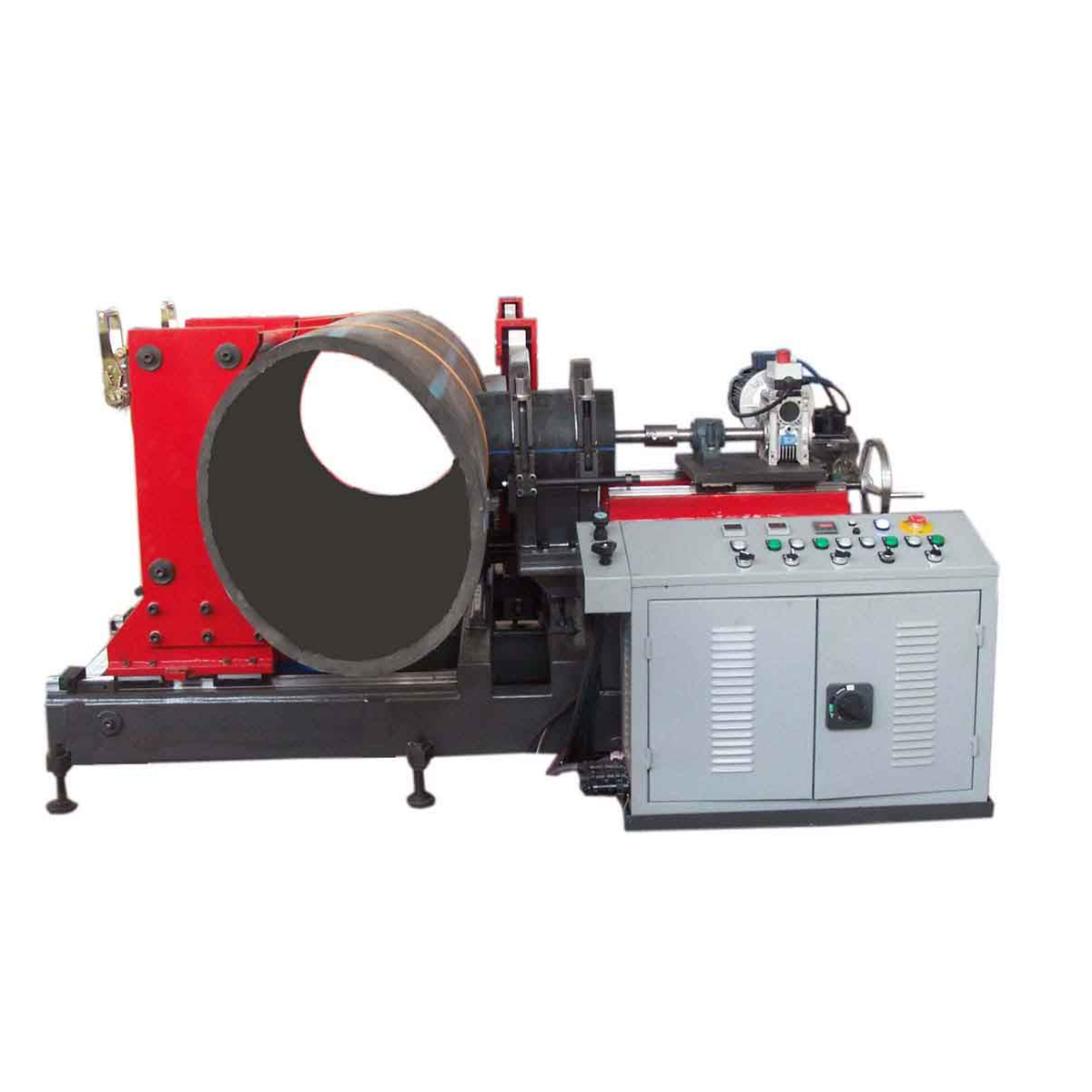

SHM630

Technical Parameters

| Specification model | SHM630 |

| Welding type | Reducer tee(see table below for details) |

| Heating plate max temperature | 270℃ |

| Max working pressure | 6Mpa |

| Working power | ~380VAC 3P+N+PE 50HZ |

| Heating plate power | 7.5KW*2 |

| Electric plate power | 3KW |

| Drilling cutter power | 1.5KW |

| Hydraulic station power | 1.5KW |

| Total power | 19.5KW |

| Total Weight | 2380KG |

| Specification model | SHM630 | ||||||

| Main pipe | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Branch pipe | |||||||

| 110 | √ | √ | √ | √ | |||

| 160 | √ | √ | √ | √ | √ | √ | |

| 200 | √ | √ | √ | √ | √ | ||

| 225 | √ | √ | √ | √ | |||

| 250 | √ | √ | √ | ||||

| 315 | √ | ||||||

Standard Composition

- A machine body with two hydraulically controlled carriages.

- A control panel that features the CNC system, thanks to this would eliminate any risk of error due to the operator.

- A milling cutter with hydraulic movement (in/out).

- A Teflon-coated heating plate with hydraulic movement (in/out).

Special reminder

1. For safety reasons, the power plug with a grounding wire must be plugged into a power outlet, and the power supply is stable. The bottom line is well grounded.

2. The user must not change the structure of the power cord plug without permission. In the event of any malfunction, the user should activate the power cord and repair it yourself.

Write your message here and send it to us