Revolutionizing Plastic Pipe Installation: The Role of Automatic Plastic Pipe Welding Machines

Introduction to Automatic Plastic Pipe Welding Machines

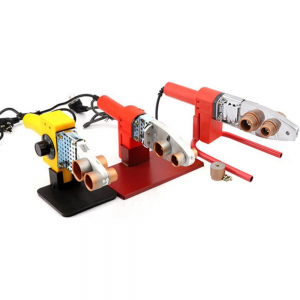

Automatic plastic pipe welding machines are designed to automate the joining of plastic pipes, a critical component in various applications such as water supply, drainage, and chemical transportation. These machines employ advanced technologies to control the welding parameters precisely, ensuring optimal fusion of the pipe joints. From butt fusion to electrofusion, these automated systems cater to different welding needs, accommodating a wide range of pipe sizes and materials.

Key Features and Benefits

● Precision and Consistency: Automated controls ensure each weld is executed with precise parameters, resulting in uniform and reliable joints.

● Efficiency: Streamlines the welding process, significantly reducing the time required for pipe installation and repairs.

● Reduced Labor Costs: Minimizes the need for skilled labor by automating complex welding operations.

● Quality Assurance: Integrated diagnostics and recording functions help monitor weld quality and compliance with industry standards.

Applications

Automatic plastic pipe welding machines are indispensable in numerous settings, including:

● Water and Sewage Systems: Ensuring leak-proof connections in water supply and sewage disposal networks.

● Gas Distribution Networks: Providing secure and durable joints in the installation of gas pipelines.

● Industrial Piping: Facilitating the construction of chemical, pharmaceutical, and food processing plants with reliable piping systems.

● Underground and Surface Piping: Enabling efficient installation of piping in challenging environments and terrains.

Choosing the Right Automatic Plastic Pipe Welding Machine

Selecting an automatic plastic pipe welding machine involves several critical considerations:

● Pipe Size and Material: Choose a machine compatible with the diameter and type of plastic pipes you work with most frequently.

● Welding Method: Consider the specific welding technique required (e.g., butt fusion, electrofusion) based on the application and pipe material.

● Portability: For projects requiring mobility, opt for a machine that balances automation with ease of transport.

● User Interface: Look for systems with intuitive controls and clear displays to simplify operation and training.

Tips for Effective Use

● Comprehensive Training: Ensure operators receive thorough training on the machine's use, maintenance, and safety features.

● Regular Maintenance: Follow the manufacturer's recommended maintenance schedule to keep the machine in optimal condition.

● Safety Precautions: Adhere to safety guidelines to protect operators and bystanders during the welding process.

● Quality Control: Utilize the machine's quality assurance features to document and verify the integrity of each weld.

Conclusion

Automatic plastic pipe welding machines represent a significant advancement in the field of plastic piping installation, offering a blend of precision, efficiency, and reliability. By embracing these automated solutions, industries can achieve superior quality in their piping systems while minimizing labor costs and installation times. Whether for large-scale construction projects or routine maintenance work, automatic plastic pipe welding machines are set to play a crucial role in the future of piping infrastructure.